-

594

5月21日,赵家镇“天府菌都交易中心”项目全......

-

Society Certification | Mr. Chen Zha......

1452

学会认证 | 凝龙合伙人陈湛二先生入选广东省......

-

RINRO | By the end of 2022, Rinro ba......

1631

为了丰富员工们的日常生活,提高员工的身体素质......

-

Yungang City Exhibition Hall | The ......

1635

本项目位于白云新城核心区,倚傍白云山畔,享C......

-

Rinro News | Rinro Building Curtain ......

1649

近日,Rinro(凝龙幕墙咨询)建筑幕墙工程......

-

Rinro participated in the preparatio......

1664

2023年(Rinro)凝龙幕墙咨询作为参编......

-

The Rinro team visited and studied t......

1699

凝龙团队参观学习第三十届国际门窗展览会

T...... -

Project Review: Dongguan Internation......

1708

项目回顾:东莞国贸中心-国际级城市综合体,东......

那双曲铝单板为什么广受欢迎?

According to big data from the aluminum veneer industry, the demand for hyperbolic aluminum veneer is steadily increasing year by year. The unique shape of hyperbolic aluminum veneer has become one of the popular building decoration materials and is highly favored by engineering and designers.

Why is hyperbolic aluminum veneer so popular?

据铝单板行业大数据显示,双曲铝单板的需求量正逐年稳步上升。造型独特的双曲铝单板,已成为常见热销的建筑装饰材料之一,深受工程方与设计师的青睐。

那双曲铝单板为什么广受欢迎?

首先,双曲铝单板具备铝单板本身的独特优异性能,其次,双曲铝单板造型多变,可根据不同曲率进行设计加工,能很好地满足设计师的建筑创意设想,让建筑物拥有良好的外观装饰展示效果。According to the big data of the aluminum veneer industry, the demand for hyperbolic aluminum veneer is steadily increasing year by year. The unique hyperbolic aluminum veneer has become one of the popular architectural decoration materials, which is favored by engineers and designers.

Why is hyperbolic aluminum veneer so popular?

First of all, the hyperbolic aluminum veneer has the unique excellent performance of the aluminum veneer itself, secondly, the hyperbolic aluminum veneer is changeable, and can be designed and processed according to different curvatures, which can well meet the designer's architectural creative ideas, so that the building has a good appearance decorative display effect.

实景图

下面我们详细来看看双曲铝单板

双曲铝单板又称曲面铝板,是以铝单板为基材,根据两种不同的弧线曲率经裁剪、折边、弯弧、焊接加筋、打磨、喷涂等多道工序加工而成的拥有两个曲面的铝单板产品。

也可以这样理解:双曲铝单板就是水平和垂直方向都是弯的造型铝单板。

Let's take a look at hyperbolic aluminum veneer in detail

Hyperbolic aluminum veneer, also known as curved aluminum sheet, is based on aluminum veneer as the base material, according to two different arc curvature through cutting, folding, bending, welding and reinforcement, grinding, spraying and other processes of aluminum veneer products with two curved surfaces.

It can also be understood in this way: hyperbolic aluminum veneer is a curved aluminum veneer in both horizontal and vertical directions.

双曲铝板

-01-

材料特性

Performance

① 具备铝单板本身的独特优异性能,质量轻、刚性好、防尘防潮防火、耐腐性和耐候性强,使用寿命长,拥有良好的抗紫外线和抗风压性能等;

② 表面纹理、色彩可选多样,装饰效果好;

③ 造型多变,展现设计曲线之美;

④ 结构设计人性化,装卸方便,便于安装施工;

⑤ 维修更换方便,可改造型强;

⑥ 温度应力小,与其他材料:玻璃、金属、石材等以柔性材料与框体连接,可以减少温度变化对结构产生的温度应力;

① With the unique excellent performance of aluminum veneer itself, light weight, good rigidity, dust, moisture, fire, corrosion resistance and weather resistance, long service life, with good UV resistance and wind pressure resistance;

② The surface texture and color can be selected, and the decorative effect is good;

③ The shape is changeable, showing the beauty of the design curve;

④ The structure design is humanized, easy to load and unload, easy to install and construct;

⑤ Easy maintenance and replacement, strong retrofit;

⑥The temperature stress is small, and other materials: glass, metal, stone and other flexible materials are connected with the frame, which can reduce the temperature stress generated by temperature changes on the structure;

实景图 ©陈尚儒

-02-

产品类型

Category

根据曲率、形状的不同常见的有球形、半球形、扭曲双弯曲、单弯曲等不同双曲率单板。

产品规格:

常规平板规格:600*1200mm,600*1500mm,1000*2000mm

最大平板规格:1200*2400mm(其他更大规格可焊接加工)

常规厚度:2.0-3.0mm

最大厚度:5.0mm

According to different curvatures and shapes, common types include spherical, hemispherical, twisted double bending, single bending, etc.

Product specifications:

Conventional flat panel specifications: 600 * 1200mm, 600 * 1500mm, 1000 * 2000mm

Maximum plate size: 1200 * 2400mm (other larger sizes can be welded and processed)

Conventional thickness: 2.0-3.0mm

Maximum thickness: 5.0mm

实景图 ©虚服摄影

-03-

加工工艺及安装要点

Processing Technic

双曲铝板是一种预制板材,需要在工厂预制成型后在现场根据图纸进行拼接,所以双曲铝板对于工厂预制精度要求很高。

1、加工工艺

常见的双曲面铝单板加工成形方式大致有以下几种:胎膜拉伸成形、利用多点成形压力机成形、机械金属模一次性冲压成形、柔性辊压三维成形、现场成形等。

① 胎膜拉伸成形

这是最常见的双曲面金属板的加工方式,首先根据设计需求制作胎膜,其次将铝板利用胶皮拉伸固定在胎膜上,工人敲击铝板使得铝板更加贴合模具,待内应力消除后裁除残缺边角,即可得到设计所需的曲面板材。

Double curved aluminum panel is a type of prefabricated panel that needs to be prefabricated and formed in the factory before being spliced on site according to the drawings. Therefore, double curved aluminum panel has high precision requirements for factory prefabrication.

1. Processing technology

The common processing and forming methods for hyperbolic aluminum veneer are generally as follows: tire film stretching forming, multi-point forming press forming, mechanical metal mold one-time stamping forming, flexible rolling three-dimensional forming, on-site forming, etc.

① Stretch forming of fetal membrane

This is the most common processing method for hyperbolic metal plates. Firstly, a tire film is made according to the design requirements. Secondly, the aluminum plate is stretched and fixed on the tire film using rubber. The worker taps the aluminum plate to make it more closely fit the mold. After the internal stress is eliminated, the missing edges and corners are cut to obtain the curved plate required for the design.

固定胎膜整体拉形示意

固定胎膜通常为木材、塑料、钢材等,胎膜拉伸成形的特点适用于大批量、同曲率铝板的成形,成形速度快,精度高,缺点是胎膜制作费用高,不适用于小批量多品种曲率的金属件。

② 多点成形压力机成形

该模具由离散的点组成,这些离散点位置可调,能够实现模具重复利用,产品误差小,但成本高,适用于小批量生产。

Fixed membranes are usually made of wood, plastic, steel, etc. The characteristics of membrane stretching forming are suitable for the formation of large batches of aluminum plates with the same curvature. The forming speed is fast and the accuracy is high, but the disadvantage is that the cost of membrane production is high, which is not suitable for small batches of metal parts with multiple varieties of curvature.

② Multi point forming press forming

The mold is composed of discrete points with adjustable positions, which can achieve mold reuse with small product errors but high costs, making it suitable for small batch production.

多点拉型模示意

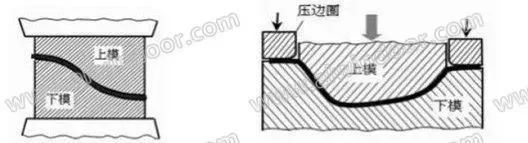

③ 机械金属模一次性冲压成形

金属模具一般分为上模与下模,利用机床液压一次性压制成型,一次性制作好模具可以实现大批量生产,但因模具制作周期和费用的限制不适合于小批量异形件成形。

Schematic diagram of multi-point drawing die

③ Mechanical metal mold one-time stamping forming

Metal molds are generally divided into upper and lower molds, which are pressed and formed in one go using machine tool hydraulic pressure. Making a good mold in one go can achieve mass production, but due to the limitations of mold production cycle and cost, it is not suitable for forming small batches of irregular parts.

机床金属模冲压示意图

机床模具还可以采用多点成形模具,能够实现复杂曲面金属板的一次成型,对产品的批量及数量没有很大要求,将模型导入电脑可以很快地实现全自动化生产,产品精度高,但机床设备昂贵,国内少见。

Machine tool molds can also use multi-point forming molds, which can achieve the one-time forming of complex curved metal plates without significant requirements for product batch and quantity. Importing the model into a computer can quickly achieve fully automated production, with high product accuracy. However, machine tool equipment is expensive and rare in China.

④ 柔性辊压三维成形

其特点是工作辊轴线可以弯曲,而且弯曲的形状可以根据需要进行控制和调整,待成形件夹持于工作辊之间,工作辊在驱动机构作用下同步转动,带动工件产生进给运动,使工作辊滚压板料,从而使板料产生纵向与横向塑性变形,可适用于多种复杂曲面造型的铝板成形,但设备价格昂贵,设备维护、调教成本也高。

④ Flexible rolling three-dimensional forming

Its characteristic is that the axis of the work roll can be bent, and the shape of the bending can be controlled and adjusted according to needs. The formed part is clamped between the work rolls, and the work rolls synchronously rotate under the action of the driving mechanism, driving the workpiece to generate feed motion, causing the work rolls to roll the sheet metal, resulting in longitudinal and transverse plastic deformation of the sheet metal. It can be suitable for forming various complex curved aluminum sheets, but the equipment is expensive and maintenance is necessary The cost of training is also high.

柔性辊压三维成形示意

⑤ 现场成形

现场成形适用于半径较大的铝单板,首先利用软件计算背筋数据对每块铝板挂点进行定位,安装钢筋龙骨支撑背筋,在关键节点安装弧形铝管作为“靠尺”,随后调整、固定铝板贴合“靠尺”,这种方式可以节约大量制作成本,但对现场施工安装质量要求很高。

2、安装施工要点

双曲铝板的安装施工,属于比较简单的,但每个环节都需要非常专业的人员支持才能够实现高还原度的建成效果。

首先三维建模计算好铝板的规格与位置,在工厂预制好铝板,然后现场施工匹配龙骨与模型坐标点,把预制好的板材安装固定到金属龙骨上。

⑤ On site forming

Field forming is applicable to aluminum veneer with large radius. First, use the software to calculate the back reinforcement data to position the hanging points of each aluminum panel, install the reinforcement keel support back reinforcement, install the arc aluminum tube at the key nodes as the "guiding rule", and then adjust and fix the aluminum panel to fit the "guiding rule". This method can save a lot of production costs, but requires high quality of on-site construction and installation.

2. Key points of installation and construction

The installation and construction of hyperbolic aluminum panels is relatively simple, but each step requires the support of very professional personnel to achieve a high degree of reduction in the construction effect.

Firstly, three-dimensional modeling is used to calculate the specifications and positions of the aluminum panel. The aluminum panel is prefabricated in the factory, and then matched with the coordinate points of the keel and model during on-site construction. The prefabricated panel is installed and fixed on the metal keel.

双曲率单板固定龙骨

-04-

应用案例

Application case

不论是在大型公建还是小型单体建筑,双曲铝板在建筑幕墙、户外景观等等方面都有出色的表现。

中国杭州电竞中心建筑表皮采用双曲面阳极氧化蜂窝铝板,在天空的映衬下,立面呈现出一种微微反射周边环境的效果。随着曲面的不同角度转换和人群视点的移动,削减了建筑的“重量”感。

Whether in large public buildings or small single buildings, hyperbolic aluminum panels have excellent performance in building curtain walls, outdoor landscapes and so on.

The facade of the Hangzhou Esports Center in China is made of hyperboloid anodized honeycomb aluminum panels, which slightly reflect the surrounding environment against the sky. With the different Angle conversion of the surface and the movement of the crowd's viewpoint, the sense of "weight" of the building is reduced.

杭州电竞中心实景图 © 奥观建筑视觉

动感流畅的银色建筑犹如时空穿梭中的“星际战舰”,连接幻想与现实,融合建筑与环境。

The dynamic and smooth silver architecture is like an "interstellar battleship" in the shuttle of time and space, connecting fantasy and reality, and integrating architecture and environment.

杭州电竞中心实景图 © 奥观建筑视觉

“冰丝带”- 中国国家速滑馆立面由金属铝板、玻璃幕墙组成,整个幕墙包含3800余块玻璃、6500块铝板,其中异形铝板达到了铝板总量的1/3,双曲铝板和双曲玻璃也达到1400余块。

"Ice Ribbon" - The facade of China National Speed Skating Hall is composed of metal aluminum panel and glass curtain wall. The whole curtain wall contains more than 3,800 pieces of glass and 6,500 pieces of aluminum panel, of which the shaped aluminum panel reaches 1/3 of the total aluminum panel, and the double curved aluminum panel and double curved glass also reach more than 1,400 pieces.

中国国家速滑馆实景图 ©Populous

中国国家速滑馆实景图 ©Populous

如同“冰痕”一般的外幕墙,采用三维建模进行排版、加工及制作,把每一处形状、角度、面积、尺寸和曲率数据逐一设计、逐一编号、逐一定制,最终像拼图一样重新组合,拼接成一个整体“冰坛”。

The exterior curtain wall, similar to the "ice mark", uses 3D modeling for layout, processing, and production. Each shape, angle, area, size, and curvature data is designed, numbered, and customized one by one, and finally reassembled like a puzzle to form a complete "ice altar".

中国国家速滑馆效果图 ©Populous

中国国家速滑馆实景图 ©Populous

上海东方体育中心建筑采用大跨度钢结构拱架和大尺寸双曲面铝板饰面。三角形桁架的所有曲面均沿下部结构框架形成同样的半径,塑造乘风破浪、扬帆起航的建筑形象。

Shanghai Oriental Sports Center building adopts long-span steel structure arch and large double curved aluminum panel surface. All the curved surfaces of the triangular truss form the same radius along the substructure frame, creating the building image of riding the wind and waves and setting sail.

上海东方体育中心 ©Marcus Bredt

结构细节 ©Marcus Bredt

烟波涟漪住宅立面选用双曲铝板,因造型独特,每一块都需要在精细的3D建模后,采用BIM软件进行分解,完成单块制作后再由专门的厂家进行双曲面铝板的焊接,制作工序多达16道,任何一处细节都不容失误。

The double curved aluminum panel is selected for the residential facade. Due to its unique shape, each piece needs to be decomposed by BIM software after fine 3D modeling, and then the hyperbolic aluminum plate is welded by a special manufacturer after the completion of a single piece. The production process is as many as 16, and there is no mistake in any detail.

烟波涟漪实景图图片

制作工艺

通过控制飘板的形状大小可以更加合理的运用自然光,避免阳光直射,并通过在上表面做约5%的坡度帮助排水,增加铝板的自洁性。

By controlling the shape and size of the floating plate, natural light can be used more reasonably to avoid direct sunlight, and by making about 5% slope on the upper surface to help drainage, increasing the self-cleaning of the aluminum panel.

示意图

铝板表层选用氟碳喷涂工艺(PVDF:聚偏二氟乙烯),经由生产线16道标准工序的处理后,即得到了两条产品线标志性的皓月银、香槟金配色,处理后的铝板表面抗紫外线、抗裂性及抗褪色性大大增强,确保外立面品质的可持续性。

Fluorocarbon spraying process (PVDF: polyvinylidene fluoride) is selected for the surface of the aluminum plate. After the treatment of 16 standard processes in the production line, the iconic bright moon silver and champagne gold color matching of the two product lines are obtained. The surface resistance of the treated aluminum plate to ultraviolet rays, crack resistance and fading resistance is greatly enhanced to ensure the sustainability of the facade quality.

烟波涟漪实景图

鹏瑞·三龙湾1号示范区景墙采用沉稳大气的20mm厚葡萄牙米黄色哑光面石材,顶部以3mm香槟金色双曲面铝板压顶。整体采用钢框架结构、饰面干挂形式,基础结构由顶板及架空板开始设计。

The landscape wall of the Perry Sanlong Bay No. 1 Demonstration Area is composed of 20mm thick Portuguese beige matte stone and topped with 3mm champagne gold hyperbolic aluminum panel. The whole adopts steel frame structure and dry hanging form of finishes, and the basic structure is designed from the top panel and overhead panel.

鹏瑞·三龙湾1号实景图

入口弧形景墙平面图

因双曲面铝板工艺要求较高,通过现场多次复尺调整方案,塑造优雅序列感与高贵体验。

Due to the high process requirements of hyperboloid aluminum panel, through the field multiple scale adjustment scheme, create a sense of elegant sequence and noble experience.

鹏瑞·三龙湾1号实景图

合肥旭辉甜甜圈幼儿园通过白色铝板在表面的流动和扭转,建筑立面在观感上显得流畅且富有韵律。木纹转印的铝板作为衬托,为建筑进一步增添了温暖和细腻的氛围。

Through the flow and torsion of the white aluminum panel on the surface, the building facade appears smooth and rhythmic. Wood grain transfer aluminum plates serve as a backdrop to further add warmth and delicacy to the building.

合肥旭辉甜甜圈幼儿园实景图 ©THDL

双曲铝板在深化过程中做了充分的优化,以此实现了模块化的加工和建筑表现力之间的平衡。而扶手采用的雾化玻璃为连续的屋面勾勒出兼顾安全与诗意的边界。

The hyperbolic aluminum sheet has been fully optimized during the deepening process to achieve a balance between modular processing and architectural expressiveness. The atomized glass used in the handrails provides a safe and poetic boundary for the continuous roof.

立面铝板分析 ©THDL

墙身大样 ©THDL

结语:

随着双曲铝单板的出现,更多异形、倾斜的幕墙设计在现实生活中得以呈现,使幕墙具有更加醒目独特的标志性,为流体建筑的兴起和发展做出了贡献,未来定将拥有更加广阔的发展前景!

Conclusion:

With the emergence of hyperbolic aluminum veneer, more irregular and inclined curtain wall designs have been presented in real life, making the curtain wall more eye-catching and unique, contributing to the rise and development of fluid architecture, and will have even broader development prospects in the future!

文章分享自“材料公社”公众号